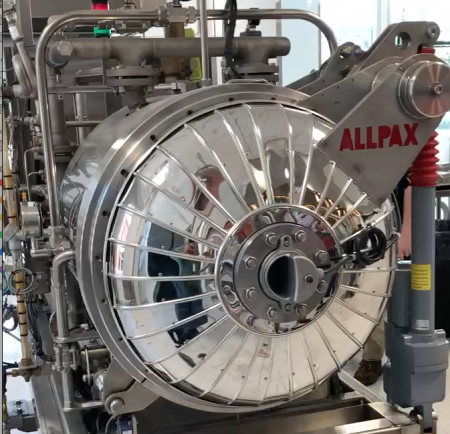

Equipment Spotlight: Allpax 2402 Multimode Retort

Part of what makes the NC Food Innovation Lab so useful to its clients is the top-tier level of equipment that is available. One of the most functional pieces of equipment is the Allpax 2402 Multimode Retort.

Since the retort processes all types of packaging, NCFIL is able to incorporate and offer many different capabilities to clients, whereas most food plants have only one or two types of retorts designed to do one specific thing in massive quantities. Flexibility is the hallmark for this size and type of retort.

Beneficial for Entrepreneurs + Large Companies

For many entrepreneurs, NCFIL is a middle step in their journey. We often help clients in the middle stages of product development, assisting in their ultimate transition into a larger production facility. Being able to evaluate products in different methods of retorting delivers flexibility to our clients before they scale up.

Large companies also stand to benefit from NCFIL’s Allpax Multimode 2402 Retort. If a large company wants to consider alternative packaging choices, it can utilize NCFIL’s retort to produce small batches of various packaging types versus taking up its normal production with small runs through their large retorts. Therefore, normal production processes continue at the same time they experiment with different packaging options at NCFIL.

Small Batches: The Way to Go

Full-scale commercial retorts are large and require a significant amount of product to fill up the retort. When a large retort doesn’t run at full capacity, it is not representative of the product’s thermal profile, which can be problematic. Therefore, being able to run small batches reduces development costs. NCFIL can run as little as 12 cans in a batch.

Allpax Retort: Making the Magic Happen

Being able to select different modes and produce in small batches are this retort’s most unique features. At NCFIL, this processing is best suited for beverages, sauces, soups and many other products that need to be sterilized in a variety of containers.

The Allpax 2402 Multimode Retort serves clients in NCFIL’s Wet Processing Area. You can take a virtual tour here. For more technical information about the retort, please see below.

—————————————————————————————————–

Allpax Retort: Technical Information

This copy was modified from Allpax Retort Shortens Development Time for Shelf-Stable Foods.

Allpax, a product brand of ProMach, created the 2402 multimode retort for developing new or enhanced food products and for quickly scaling up to production.

- Features rotary and horizontal agitation and saturated steam and water immersion modes

- Includes Allpax’s new pressure profiler that delineates cook and cooling process parameters to ensure package integrity by minimizing package deformation and stress during the sterilization process

- Delivers the capability to develop entirely new product categories or refresh existing products with improved quality and taste by utilizing the large number of available process combinations and profiles

- Accomplishes changeover between modes via software and/or hardware

- Processes all types of packaging including metal or plastic cans; glass or plastic bottles; glass jars; plastic or plastic cups, trays, or bowls; fiberboard containers; plastic or foil laminated pouches, etc.

- Incorporates the production version of Allpax control software, which is FDA 21 CFR Part 11 compliant for recipe editing, batch logs, and security functions.

- Ensures internal production operations and the ability for co-packers to accurately replicate process parameters by using the same control solution for lab and production units.

AGITATION CAPABILITIES

- Static

- End-over-end agitation

- Rocking

- Gentle Motion

- Shaka Process®

- Axial rotation

- Hydrostatic sterilizer simulation

PROCESS CAPABILITIES

- Saturated Steam

- Full or Partial Water Immersion

- Steam-Air Overpressure

- Water Spray w/Overpressure

- Water Cascade w/Overpressure

- Categories: