Equipment Spotlight: GEA Mobile Minor Spray Dryer

The GEA Mobile Minor Spray Dryer has become one of the more popular pieces of equipment at the NC Food Innovation Lab. Over the last four months, it’s been used in at least one project a week, and the staff at NCFIL is excited about future collaborations.

What Does It Do?

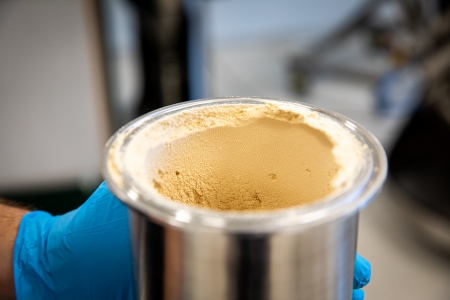

Spray dryers turn liquids into powders; those powders are used as food ingredients to go into finished food products. Powdered flavors for drink mixes, some instant coffee powders and protein powders are all examples of products that involve the use of a spray dryer.

NCFIL has used its spray dryer to work on a spray-dried juice powder, protein powders, and a sweetener blend. Joseph Hildebrand, NCFIL’s Pilot Plant Manager, says they’re also talking about opportunities to work on natural flavor powders, enzyme modified proteins, food ingredients created from food byproducts, and botanical extracts isolated from plant sources, such as tea and coffee.

How Does It Work?

Turning a liquid into a powder sounds a little like magic, but here’s the science behind it, as explained by Hildebrand.

You pump a liquid into the system where it combines with an atomizing gas – usually air – that disperses the liquid through a nozzle forming a fine mist. The mist is distributed into the drying chamber where it hits superheated air, in turn vaporizing the water content in the mist particles. You’re left with a dry, soluble powder.

Who Would Use It? And Why?

Designed to be an R&D spray dryer, the Mobile Minor is perfect for those who want to try a spray dryer for the first time or fine-tune a process they have already been using. It works well for pilot-sized projects since it produces small quantities of powder samples, and NCFIL’s state-of-the-art pilot plant is the perfect place to test it out.

The spray dryer is used on the food ingredient side of development and production rather than part of producing a finished product, which makes it less relevant to entrepreneurs who are looking to bring a food product directly to the market. Many start-up companies working on unique food ingredients are interested in using a smaller spray dryer to develop their process.

“Most clients we have used it with have been multinational companies with their own large-scale spray drying capability. We’ve been fine tuning and evaluating process adjustments for them,” says Hildebrand.

Others who would work with the spray dryer include companies looking at value-added materials from food byproducts. For example, cheese production produces liquid whey. The spray dryer can take that whey liquid byproduct and produce powdered whey to use in other food products. It’s also useful for companies experimenting in plant science. There is still so much to learn about different extractions of plant materials and looking at specific plant compounds for their health and wellness benefits. It is easier to store and ship powder than liquid, so the spray dryer can help us gain knowledge of plant-based food sources.

What Are the Benefits of THIS Spray Dryer?

Well-established in the food processing industry, GEA produces many different kinds of food manufacturing equipment, including larger scale spray dryers. The Mobile Minor’s settings are designed to match up with GEA’s larger units, which decreases lead time when moving to full-scale production. This may be the largest benefit of all.

And as its name indicates, it is mobile, mounted on castors, so it’s convenient to move around. While the spray dryer has a “home base” at NCFIL, the entire facility was designed with flexible equipment layouts in mind.

NCFIL’s Role

Hildebrand explains that there is a steep learning curve to using the Mobile Minor, and even once you’re comfortable with it, every product you run through it is different. “It takes a while to find the ‘sweet spot’ of the spray dryer with each specific material, such as percent solids, inlet and outlet temperatures, and types of atomizers. We play with inputs and outputs to optimize conditions.”

If you’re interested in trying out the GEA Mobile Minor Spray Dryer, we’re ready to partner with you!

- Categories: